This non standard equipment needed some brainstorming because we did not want the pump, radiator and filter to be damaged by flying objects.

Luc made some cardboard moulds before making the final (pump)support.

Since welding aluminum is piece of cake nowadays the support was ready in a trice.

We just needed to fold a protection plate and everything is safely tucked away.

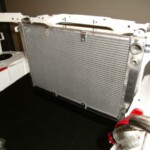

We needed to develop a big radiator because we did not choose a traditional oil cooler but a Laminova heat exchanger (oil-water). This means we also cool our oil by means of the cooling water flowing through the radiator.

We bought a custom made “high efficiency” net and we needed to make the rest of the radiator ourselves. It is not finished yet but it only needs some final welding.

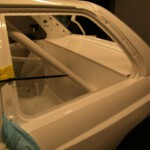

Since we needed to deliver the car at the paint shop on saturday morning some guys of the team did not sleep much on friday night.

Dirk (=handy man) does not like silicones at all (watch out ladies !) and therefore Ivo was prepared to make the BMW waterproof by filling all the holes and gaps with sticky silicone.

Because Ivo is not a real giant he fits very well in between the roll cage pipes but sometimes we heard a loud curse coming from the trunk…

Since the body work has come to an end we would like to thank all the bodyshoppers for all their “voluntary” work been done ! It is much appreciated !