If we are to believe everyone, the first time is always a bit special. Fortunately, the conditions were ideal, plenty of sun, bone dry and assisted by a very experienced co, Isidoor Smets, who stepped in last minute for Luc Geenen. Add to that a super nice car, 4 super mechanics and mega coach / cooking mom and numerous sympathizers, in short the perfect ingredients for a fantastic rally.

It has been quiet for a very long time on the R-Box site, this was on the one hand a very conscious choice and on the other hand we have been working very diligently on the car, service truck and other infrastructure, so that there was very little time left to add stories here.

Because we have now reached an important milestone, it might be nice to post something new again. GOOD news this time!!

We have already had some sleepless nights but we are on the right track despite the failure of our homemade laser alignment tool.

We had conceived the bright idea of placing a laser module in the center point of the drive shaft on the Vbak. The theory was then to raise the Vbak until the laser cross was projected into the center point of the differential. However, turning the Vbak exit taught us that the center point did not stay in place. We attributed it to the lack of precision of the lathe but it could just as well have been a faulty turner because we had made that tool ourselves

But don’t worry we’ll get it right. On Monday, 12mm uniballs are ordered, the rubbers to give the box a very small amount of freedom of movement we have already turned and then we only have to think about making a height-adjustable Vbak support.

Too long ago that an update has happened on the site but this has everything to do with a chronic lack of time.

Fortunately, the BMW does get shapes even though it does not go as fast as we would like, but we have to row with the resources we have. Fortunately, in recent weeks we have become a lot more numerous on Saturdays, which is highly privileged.

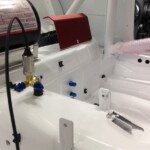

Despite a few small problems, the entire back is now ready. We still had to adjust the plate of the ATL tank because we didn’t really get away with the flexible. We also modified the fuel cap, which was a screw version. The goal was to elliminate everything that can be lost, not that we don’t have confidence in our mechanics

We also struggled a bit with the bolts of the topmounts, but after redrawing them 3 times and a multitude of assembly attempts, we can finally make peace with the result.

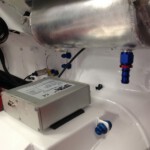

As you can see, the cablage has been able to remain very limited. All rear lights + the 3 petrol pumps are controlled by 1 PWR-Box

Because we were not raised from home in an imperial world, this is really 1 big puzzle. I still don’t understand what those American army men think about that now.

I ordered about 2 A4 pages full of different nipples. With Frank’s nightly assistance, we even tried to put that schematically on paper. Phase 1 is now behind us. All coupling pieces have been assembled and now we can start measuring all the pipes to order them as soon as possible.

We assume that the assembly of the leads is super fast so the biggest work is done here.

They are still very limited in number, but the main power lies in them.

Because the battery is at the very back and the BMW heart has a very significant dose of compression, we can miss any kind of voltage drop over the cable like the plague.

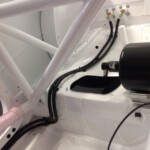

Hence the overgrown 50mm2 cables that we have safely steered through the back wall and bulkhead in our own way.

In order for the “big” cables not to be secured, we have paid some attention to this. Armed with a bar OF POM and a copper threaded rod, Luc has made custom made penetrations. Safety first !!

Now we only have to find suitable rubber covers to insulate the nuts.

Sunday 5 May was the annual open day for the Technical Institute Sint-Paulus in Mol.

Since these people have helped us countless times, we could not be missed on the apple. During the tour through all the departments we were really surprised how well equipped this school is. From modern CNC machines to a fully equipped garage department with even a power roller test bench. In the mechanics department, some parts of our BMW were also exhibited.

We would therefore like to take this opportunity to express our gratitude for the help we have provided so far.

Thank you Jorn, Peter, Carlo and all the students who participated in this !!

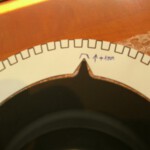

Because we are not really wild about all the “non-BMW origin” crankshaft pulleys that are sold here and there, we also had to make some adjustments for this. What worried us most was the fact that these pulleys are always made without a damper. Even though the S14 crankshaft is fairly sturdy in origin, this did not give a good feeling.

For the radiator we initially tried to find our salvation in something that exists but for 1 reason or another it turned out not to fit. Both the Mitsu and Subaru radiators are a few cm’s too big. The Sierra Cosworth radiator came closest in terms of width but is then a bit too low so that you also lose cooling capacity there.