Sometimes a solution can be very simple, unfortunately most manufacturers don’t aim to please!

Basically this story had ended but our 45 degree rotating disc to place the TPS sensor onto the actuator wasn’t state of the art production. We thought it would be so simple that we wouldn’t even have to bother our mechanical guru Nick but nothing could be further from the truth.

To avoid having to admit that I had been premature about the simplicity of the installation I thought I could remake the axle of the actuator and rotate the cogwheel 45 degrees.

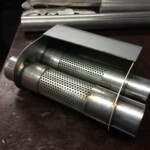

Apparently this was more complicated than we thought and manufacturer Jenvey wasn’t really up to it. Another even more simple solution would be that instead of having 2 fixation points for the sensor they would foresee multiple fixation points but yet again our UK manufacturer wasn’t feeling up to it. Strange actually when you think of it because the easier to use the more they would be able to sell them. Because there’s was no collaboration from the UK we were forced to become creative yet once more and we moved the sensor to the back and made a joining piece with a 45 degree twist. Unfortunate but couldn’t be helped. Plus side is that we now can use an P&G sensor.